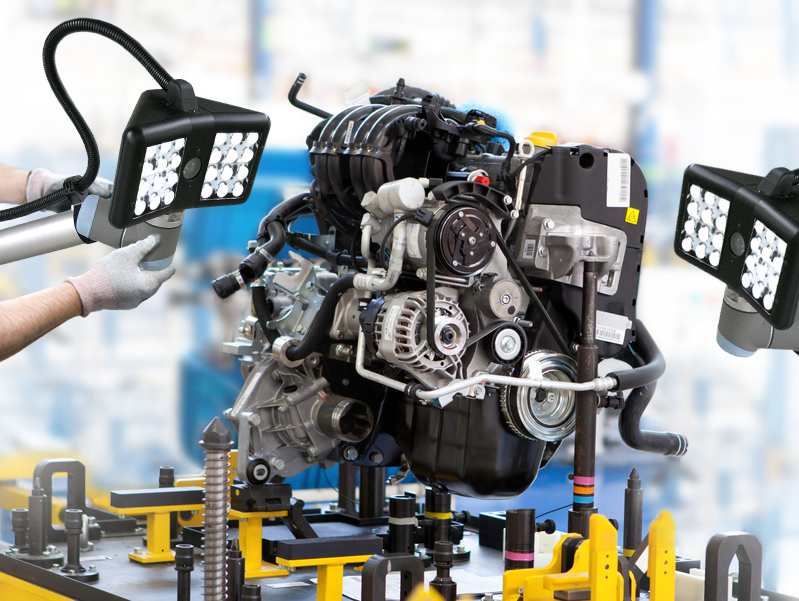

Quality controls with camera systems are a proven means of avoiding errors. This also applies to axle assembly in automotive engineering. After a series of assembly steps, completeness, type variant and alignment of various add-on parts are checked. Whether the presence of the cable holders, cable pull holders and star sheaves, correct caulking of the collar nut, variant checking by code reading or on the basis of part-specific forms, the list of features to be checked is long.

基于视觉系统的质量控制是一种行之有效的避免缺陷的方法。这也适用于汽车工程中的动力总成装配。在一系列的装配步骤之后,检查各种附加部件的完整性、类型变化和对齐状态。要检查的特征会很多,比如电缆固定器有无、电缆拉固定器有无、星形滑轮有无、凸缘螺母是否正确填缝、通过代码读取或基于零件特定形式进行的变体检查,。

Depending on the complexity of the features and their position in different variants, many inspection areas must also be covered with cameras and associated lighting. Conveyed on a part carrier into an inspection cell, many cameras and lighting systems are often required in such quality gates in order to acquire all features and variants. The use of the robot-guided camera results in almost limitless flexibility. Not only can any additional features be integrated into the inspection process in just a few simple steps, but the operator of the system can also look forward to future variants. While new derivatives, due to their partly different design, made it necessary to repeatedly expand test cells with permanently mounted cameras and lighting, it is now sufficient to adjust the test position and analysis feature.

根据特征的复杂性及其在不同变体中的位置,许多检查区域还必须被相机和相关照明覆盖。为了获得所有特征和变体,通常需要在这样的quality gate中需要非常多的相机和照明系统。我们独特设计的ROBOcam测头,为这个检测带来了几乎无限的灵活性。不仅可以通过几个简单的步骤将任何附加检测特征集成到检查过程中,而且系统的操作员还可以很好的处理对以后的新的变体的检测。由于新产品变体与现有产品的设计存在部分不同,传统检测方式必须不断增加固定安装的新摄像头和照明设备来反复扩展测试单元,实现对新变体的检测。但现在我们的ROBOcam测头足以灵活的调整测试位置和分析功能,实现对新产品变体的检测。

Special knowledge for handling the robot is not necessary. The camera can be moved manually to the desired position by weightless switching of the robot. The V60 image processing software transfers the position to the position list by mouse click and saves it as a type variant and inspection characteristic. The cameras used are equipped with 36x zoom and enable an adapted image area, focus and brightness for each inspection feature, which are also acquired in the type and feature list.

操作机器人不需要专门知识。通过机器人的无重量切换,相机可以手动移动到所需位置。我们的图像处理软件通过鼠标点击将位置发送到位置列表,并将其保存为特定变体种类的特有检测。所使用的相机配备了36x变焦,可以为每个检测特征启用自适应图像区域、焦距和亮度,这些也在变体种类和特征列表中获取。

The camera system with the VisionTools V60 image processing software not only inspects all features, but also manages all associated robot positions and controls their movement. The user therefore only has to concentrate on one user interface, which considerably simplifies the handling of the system.

我们的视觉系统不仅检查所有特征,还管理机器人的所有相关位置并控制其移动。因此,用户只需专注于一个用户界面,这大大简化了系统的使用。